How to Build a Giant Hidden Shelf Edge Clock

We had a large space on part of our living room wall for which we could never find the right 'thing' to hang on it. After trying for several years we decided to make something of our own. This turned out rather well (in our opinion) so I turned it into a project on my Youtube channel and a written a guide which you're reading right now!

It's a giant digital LED clock discreetly hidden in the edges of a geometric shelving system. It also included integrated LED downlighters to show off your favorite items on the shelves.

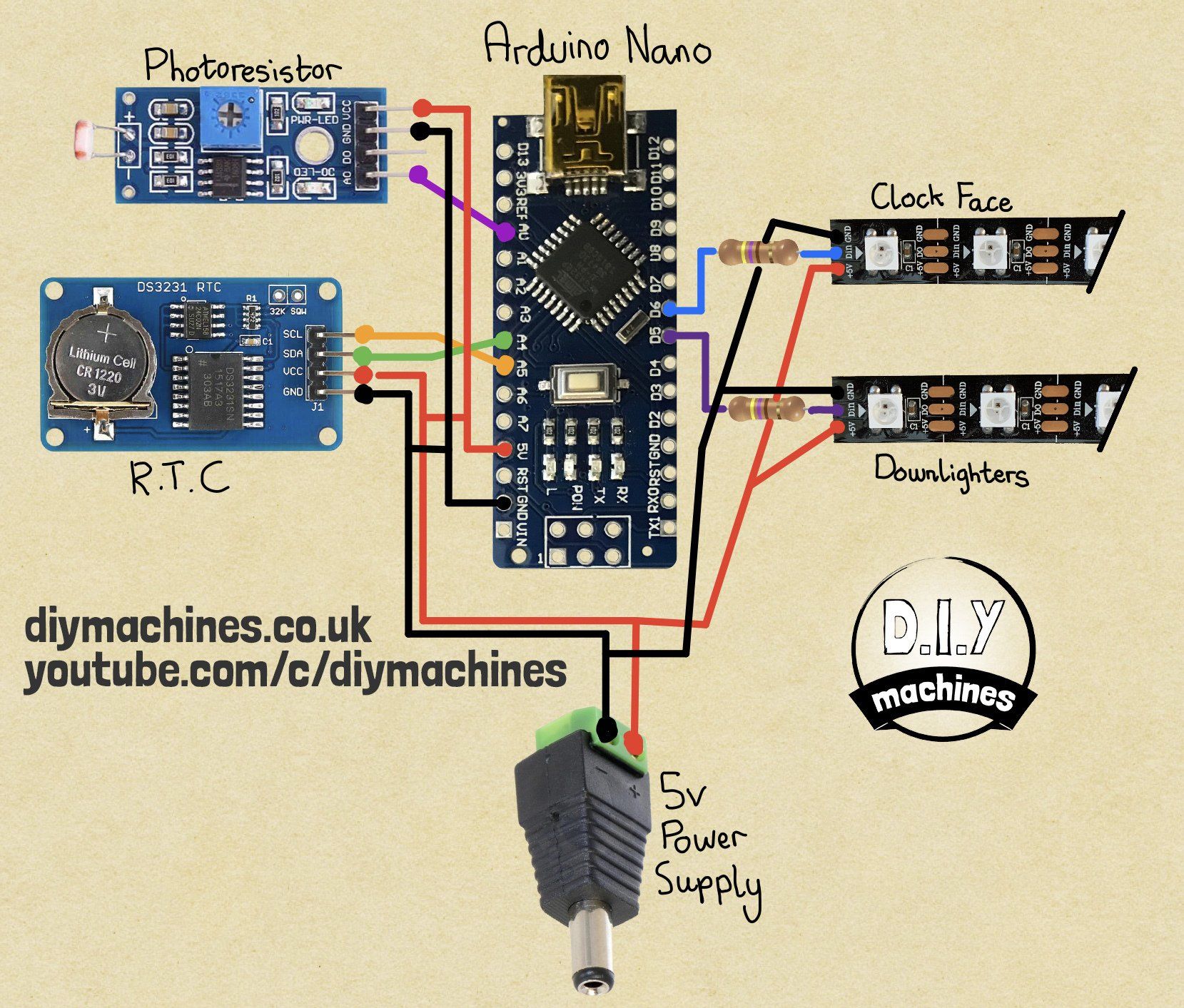

As the lighting is LED (using WS2821B 'Neopixels') you can choose your own colours - both for the clock face and downlighters. A discreet photoresistor is hidden in the top right corner which dims the LED's when the ambient light levels drop - great for evening ambiance in any room.

DISCORD server: https://discord.gg/EhqqePPcKk

Code and other downloads

Code for the project can be found on its Github page: https://github.com/DIY-Machines/DigitalClockSmartShelving

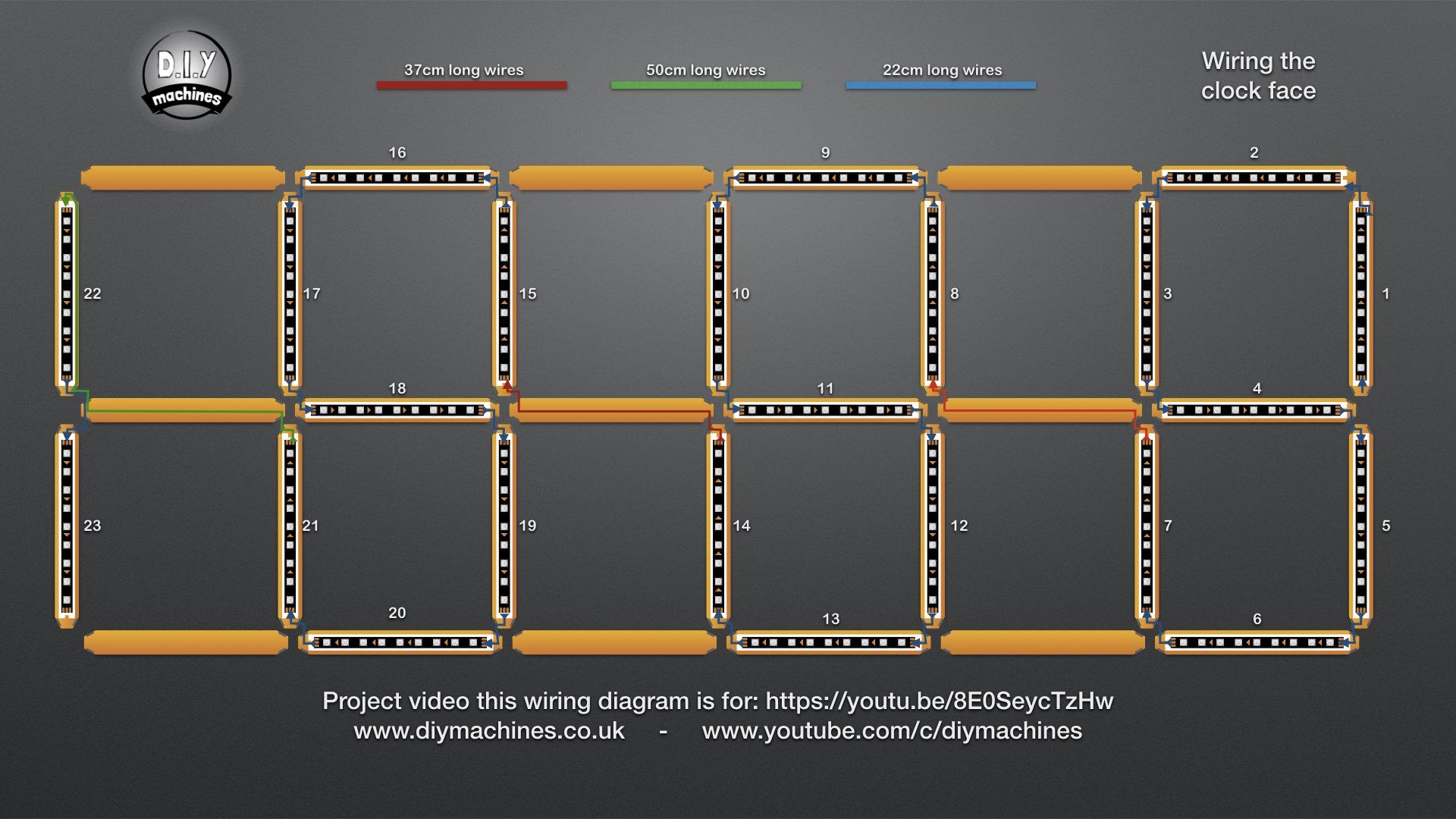

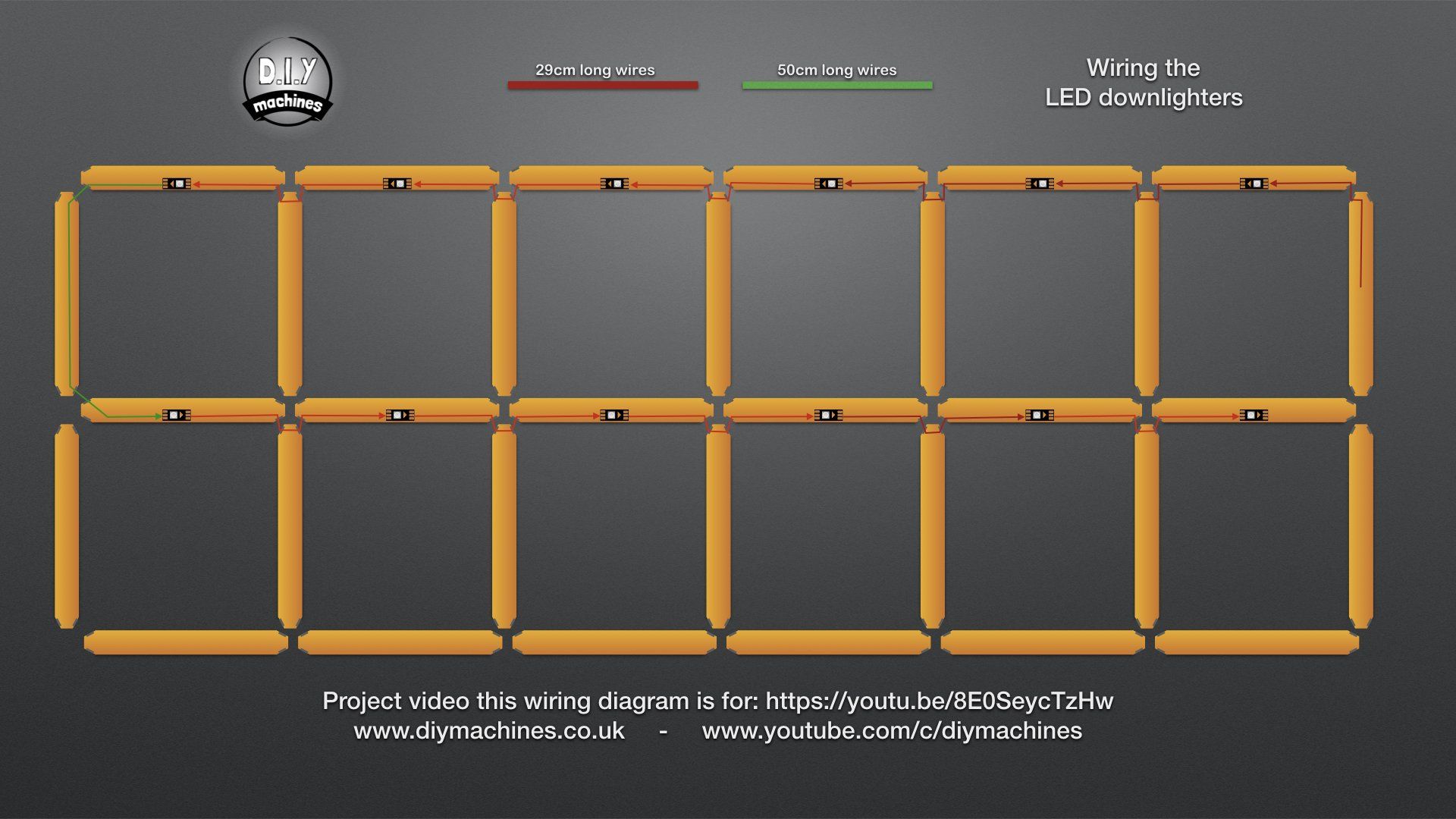

3D printed parts and wiring diagrams can be downloaded from here: https://www.prusaprinters.org/prints/94364

Drawing for CNC drilling of the backboard (if you have access to a CNC machine or know someone else who does):

https://www.etsy.com/uk/DIYMachines/listing/1081760909

DISCORD server: https://discord.gg/EhqqePPcKk

Wiring Diagrams

Click on an image to see a larger version.

FAQ's